Unsupported Browser

This website does not support Internet Explorer 11.

Please use a modern browser like Google Chrome or Mozilla Firefox.

Ramping up, distantly

Now, at a time when people need to maintain a 6-foot distance between themselves and the rest of the world’s population, Chroma is ramping up its manufacturing. “One company we make lenses for got an order last Friday for close to $1 million,” Millman said. “That company needs to build these machines as fast as they possibly can do it.” He added that the firm fielded a questionnaire from the company: “‘Can you supply us? Can you continue to supply us on time when we increase our volume? When we double our value?’” “So we are sitting in the position of having to supply these systems, these companies that make these systems, and they have the highest priority. We also have other customers, but these have the highest priority right now.” How is the company working to deliver these orders? “We have the most bizarre scheduling I’ve ever imagined,” Millman said. “And [our workers have] done an incredibly good job. In all the departments that we have, we can work at any given moment with half the number of people. We’ll be able to continue manufacturing even with the shutdown. We’re going to put some more people on, but mostly we’re just doing it with creative shifts and creative scheduling. ” In terms of dollars, Millman estimated that the COVID-19 virus will add about $2 million more to the employee-owned company’s bottom line. “So, if last year we shipped $34.5 million, this year we’ll ship closer to $38 million, or maybe even $39 million,” he said. “And this has been just in the last two weeks. Our shipments over last year’s are over 10 percent higher. But they will be higher than that in order to meet the demand.” Millman observed that Chroma is not alone. “I think that anybody who is in a medical field, with those kind of customers, is experiencing this,” he said." ["post_title"]=> string(56) "Bellows Falls Firm’s Products Play Key Role in Testing" ["post_excerpt"]=> string(0) "" ["post_status"]=> string(7) "publish" ["comment_status"]=> string(6) "closed" ["ping_status"]=> string(6) "closed" ["post_password"]=> string(0) "" ["post_name"]=> string(42) "bf-firms-products-play-key-role-in-testing" ["to_ping"]=> string(0) "" ["pinged"]=> string(0) "" ["post_modified"]=> string(19) "2020-12-13 12:20:02" ["post_modified_gmt"]=> string(19) "2020-12-13 16:20:02" ["post_content_filtered"]=> string(0) "" ["post_parent"]=> int(0) ["guid"]=> string(28) "https://www.89north.com/?p=1" ["menu_order"]=> int(0) ["post_type"]=> string(4) "post" ["post_mime_type"]=> string(0) "" ["comment_count"]=> string(1) "1" ["filter"]=> string(3) "raw" }Home » Bellows Falls Firm’s Products Play Key Role in Testing

Bellows Falls Firm’s Products Play Key Role in Testing

BELLOWS FALLS—Restaurants may be closed, supermarkets may display empty shelves, and small businesses may be afraid of going bankrupt, but at least one Windham County company is doing well in the heart of the COVID-19 virus pandemic.

Chroma Technology, which manufactures optical filters for the scientific, biomedical, photonics, and imaging industries, is facing an unprecedented call for its products.

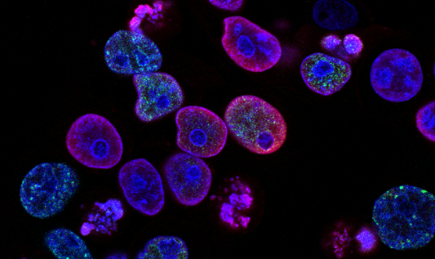

“An optical filter takes light and breaks it into its component colors,” Chroma CEO Paul Millman told The Commons in a March 25 interview. “And there are tests dependent on seeing the fluorescence of something.”

“Sometimes they use our filters at 0 degrees,” Millman continued. “Sometimes they’re tilted. Sometimes they’re bigger, and sometimes they’re smaller. Sometimes they go into a robot. Sometimes they go into a microscope. They’re all optical filters.”

Right now, the world is consumed by science, and the demand for new optical filters — and new kinds of optical filters — is strong and growing stronger. Chroma’s biggest problem could be meeting the onslaught of demands.

Today, in laboratories around the world, scientists are frantically working on tests for and vaccines against the COVID-19 virus that is keeping more than half the world in quarantine.

PCR, or polymerase chain reaction, is “the primary instrument for testing this virus,” Millman said. The technology takes genetic material from a nasal swab and amplifies it, building up enough of a quantity for technicians to get a measurable result.

When DNA and other chromosomes are stained with a material that fluoresces, Chroma’s filters make them visible in color.

“There are variants on the theme, having to do with imaging, quantitativeness and automation, but PCR is the umbrella technology,” he added. “The demand for that instrument has grown dramatically. The demands on the part of the companies that make that instrument has grown dramatically. And the demands on us, by those companies, has increased dramatically just the last three weeks.”

The company, founded in 1991, employs more than 150 people in Bellows Falls. It also has offices in Xiamen City, China and Yokohama, Japan.

“Our first work was with people who were doing genetic testing for cancer and a whole assortment of genetic diseases, including Down syndrome,” Millman said. “And what we were doing is making optics that allowed scientists and clinicians and lab technicians to easily see these things because they are in color.”

Ramping up, distantly

Now, at a time when people need to maintain a 6-foot distance between themselves and the rest of the world’s population, Chroma is ramping up its manufacturing.

“One company we make lenses for got an order last Friday for close to $1 million,” Millman said. “That company needs to build these machines as fast as they possibly can do it.”

He added that the firm fielded a questionnaire from the company: “‘Can you supply us? Can you continue to supply us on time when we increase our volume? When we double our value?’”

“So we are sitting in the position of having to supply these systems, these companies that make these systems, and they have the highest priority. We also have other customers, but these have the highest priority right now.”

How is the company working to deliver these orders?

“We have the most bizarre scheduling I’ve ever imagined,” Millman said. “And [our workers have] done an incredibly good job. In all the departments that we have, we can work at any given moment with half the number of people. We’ll be able to continue manufacturing even with the shutdown. We’re going to put some more people on, but mostly we’re just doing it with creative shifts and creative scheduling. ”

In terms of dollars, Millman estimated that the COVID-19 virus will add about $2 million more to the employee-owned company’s bottom line.

“So, if last year we shipped $34.5 million, this year we’ll ship closer to $38 million, or maybe even $39 million,” he said. “And this has been just in the last two weeks. Our shipments over last year’s are over 10 percent higher. But they will be higher than that in order to meet the demand.”

Millman observed that Chroma is not alone.

“I think that anybody who is in a medical field, with those kind of customers, is experiencing this,” he said.